Understanding the Tevo Tarantula Bed Issues

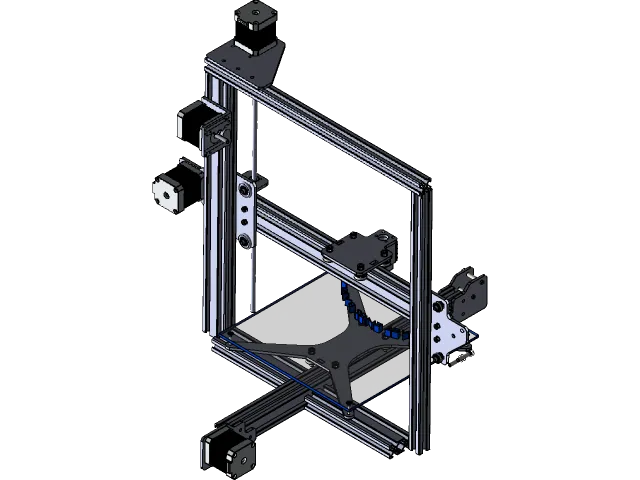

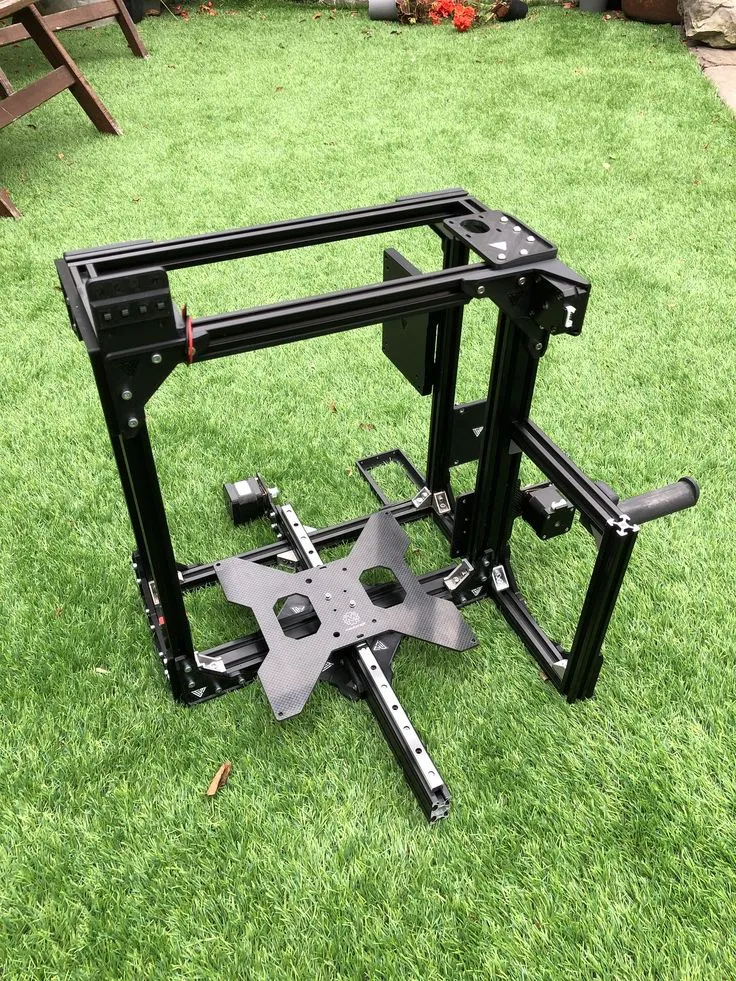

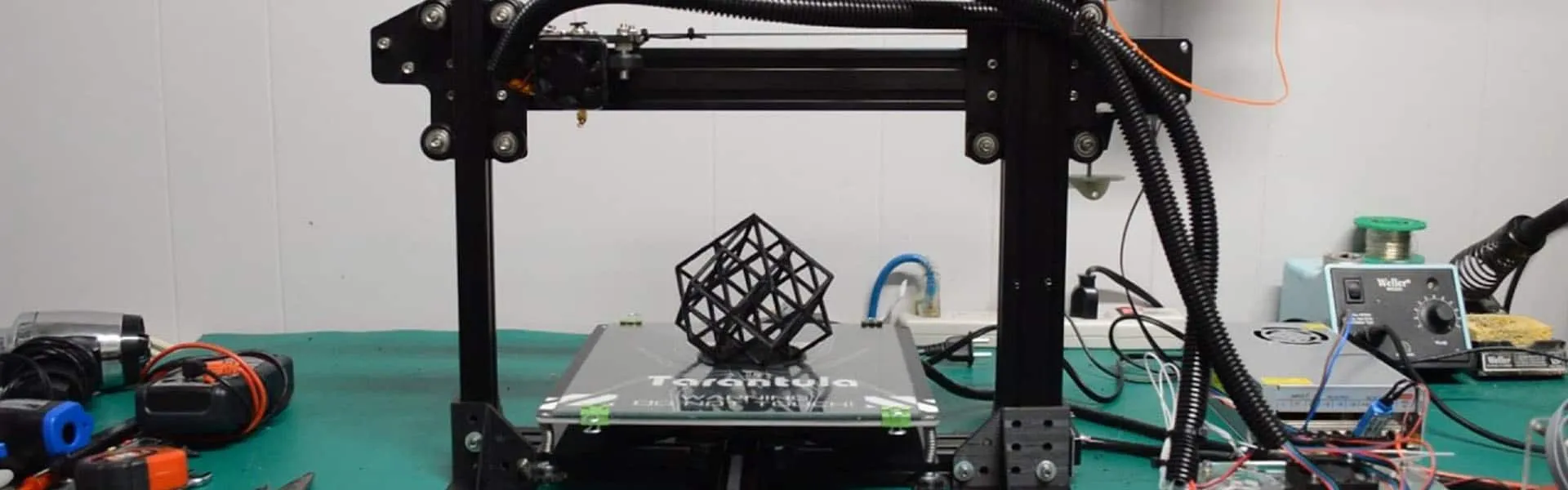

The Tevo Tarantula, a popular entry-level 3D printer, offers a fantastic platform for hobbyists and enthusiasts. However, achieving consistently smooth prints often requires attention to detail, particularly regarding the printer bed. Understanding the common issues that affect bed smoothness is the first step toward resolving printing problems. These issues can range from simple problems to more complex ones. Common problems can be caused by many factors. Addressing these challenges ensures successful and high-quality 3D prints. The bed’s condition significantly impacts the first layer, which acts as the foundation for the entire print, therefore it must be perfect.

Common Problems Affecting Bed Smoothness

Several factors can contribute to a rough or uneven first layer, leading to poor print quality. Understanding and identifying these issues are crucial for troubleshooting and improvement. The most frequent problems include bed leveling difficulties, inadequate bed adhesion, and nozzle-related issues. These problems, if unresolved, will result in the print detaching mid-print. Moreover, the bed surface’s condition and the printer’s parameters can affect the overall print smoothness and successful completion. Addressing these common problems proactively can significantly improve the print quality and experience.

Leveling Problems

Incorrect bed leveling is one of the most common culprits behind poor print quality. An unlevel bed causes the nozzle to be too close to the bed in some areas and too far in others. This results in inconsistent layer adhesion and a rough first layer. Even a slight tilt can be very problematic for print quality. The first layer is the foundation, and any irregularity is directly reflected in the print’s surface. This results in a frustrating experience. Regular calibration is vital to counteract this.

Bed Adhesion Problems

Poor bed adhesion prevents the print from sticking to the bed, which results in warping, peeling, and failed prints. This can be caused by a variety of factors, including a dirty bed surface, the wrong print surface, or improper use of adhesives. Materials will warp, or simply detach from the printing bed and ruin the print in its early stages. If this happens, the only solution is a restart with adjusted parameters or additional solutions to improve adhesion. Properly addressing bed adhesion is essential for a successful 3D printing experience.

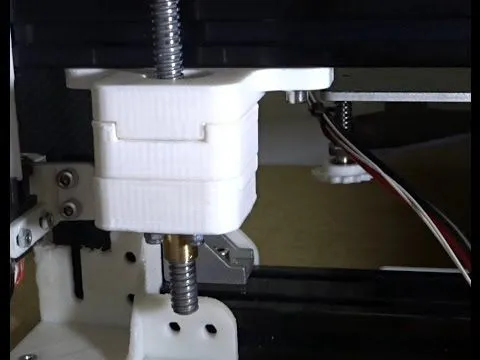

Nozzle Issues

Nozzle-related issues, such as a clogged nozzle or incorrect nozzle height, can directly impact print smoothness. A clogged nozzle restricts filament flow, creating an uneven extrusion and inconsistent layers. Similarly, if the nozzle is too close to the bed, it can scrape the filament, leading to a rough surface. Conversely, if the nozzle is too far from the bed, the filament won’t adhere properly. Regularly inspect and maintain your nozzle to ensure optimal print quality. Always clean the nozzle before starting the print to minimize issues.

Preparing Your Tevo Tarantula for Smoothing

Before smoothing your Tevo Tarantula’s bed, proper preparation is essential for success. This involves cleaning the bed surface and gathering the necessary tools and materials. A clean and well-prepared bed maximizes adhesion and ensures optimal printing conditions. Proper preparation streamlines the process. This reduces the chances of problems and improves overall print quality. Taking the time to prepare is a worthwhile investment in achieving smooth and successful prints.

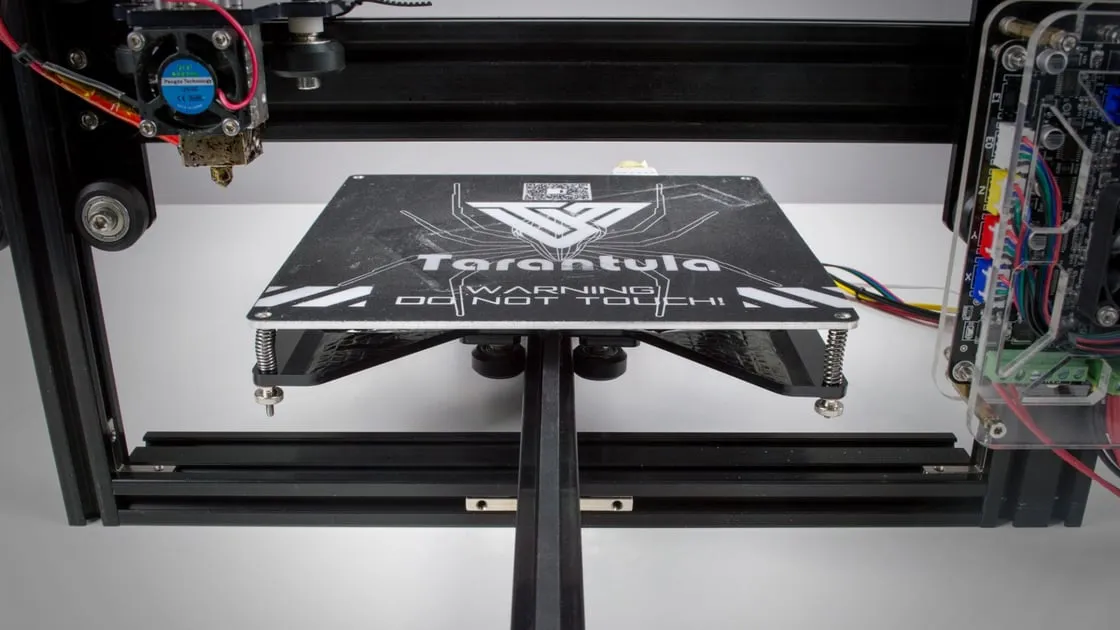

Cleaning the Bed Surface

A clean bed surface is crucial for good adhesion. Remove any residue, dust, or oils. Use isopropyl alcohol (IPA) and a clean cloth. Wipe down the bed surface thoroughly. Cleaning removes any contaminants that could interfere with the filament’s adhesion to the bed. For persistent residue, you can use a specialized 3D printing bed cleaner. This cleaning ensures a pristine surface for printing. Proper cleaning should be done before every print.

Gathering Necessary Tools and Materials

Gathering the right tools and materials is a crucial step. This includes isopropyl alcohol, a clean cloth, a level (or bed leveling sensor), and any bed adhesive, such as glue stick or painter’s tape, if needed. Having these tools readily available streamlines the process. This minimizes downtime and facilitates smoother operation. Preparing beforehand means you have everything at hand when you need it. This makes it easy to start troubleshooting and fixing problems.

How to Level Your Bed

Bed leveling is a critical step in achieving a smooth first layer. Properly leveling the bed ensures that the nozzle is the correct distance from the bed across the entire printing surface. If not properly leveled, the print will not adhere to the bed and be a complete waste of time and material. Here are a few methods to level the bed correctly.

The Importance of Bed Leveling

Bed leveling is the foundation of high-quality 3D printing. When the bed is level, the nozzle dispenses the filament evenly. This results in a consistent first layer and a smooth, successful print. Incorrect leveling leads to uneven extrusion, poor adhesion, and warping. The printer should be leveled every time before printing to ensure perfect results.

Leveling Methods

Several methods are used to level your Tevo Tarantula bed, each offering its benefits. You can use the paper method or utilize a bed leveling sensor. Choosing the right method depends on your comfort level, the printer’s setup, and your desired precision. You can learn the paper method easily. Sensors help you achieve a more precise and automated leveling.

Using Paper Method

The paper method is the most common. First, heat the bed and nozzle to printing temperature. Then, move the nozzle to each corner of the bed. Place a piece of paper between the nozzle and the bed. Adjust the bed leveling screws until the nozzle lightly grips the paper. Repeat this process for each corner, ensuring consistent resistance on the paper. This method relies on your sense of touch. It requires a bit of practice to master, but is the most common.

Using a Bed Leveling Sensor

Bed leveling sensors, such as the BLTouch, offer a more automated approach. These sensors automatically measure the distance between the nozzle and the bed at multiple points. The printer’s firmware then compensates for any bed irregularities during printing. Installing and configuring a bed leveling sensor requires a bit of technical knowledge. But, it significantly simplifies the leveling process. This results in more consistent and accurate prints.

Achieving Perfect Adhesion

Achieving perfect bed adhesion is vital for print success, preventing warping and detachment. Choosing the right adhesives and print surfaces is critical. This allows the print to stick properly to the bed and ensures a smooth first layer. Using the correct method helps to solve many adhesion-related problems, leading to higher quality prints and minimal frustration.

Applying Adhesives for Best Results

Several adhesives are available to improve bed adhesion. Glue sticks are an affordable and effective option. Apply a thin, even layer to the bed surface. Alternatively, painter’s tape can be used, especially for specific materials. Hair spray is another choice for some materials. Experiment to see what works best for your filament. The goal is to create a surface that the filament can grip onto during the printing process. The correct choice will depend on the material.

Choosing the Right Print Surface

Choosing the right print surface can enhance adhesion. The Tevo Tarantula often comes with a basic heated bed, but there are many upgrades. Consider upgrading to a glass bed, which provides a flat and smooth surface. PEI sheets or BuildTak are also popular choices. These materials offer good adhesion and are easy to remove prints from once cooled. Choosing the right print surface combined with correct leveling and adhesive use greatly increases the likelihood of smooth prints.

Optimizing Your Printing Parameters

Optimizing your printing parameters can help ensure bed smoothness. This includes fine-tuning the bed temperature, adjusting the first layer height, and controlling the nozzle temperature. Each parameter affects print quality. Fine-tuning these settings is a crucial step in achieving a smooth first layer and overall successful prints.

Fine-Tuning Bed Temperature

Bed temperature plays a critical role in adhesion, especially with materials like ABS and PETG. Setting the correct temperature allows the first layer to adhere correctly. The ideal temperature depends on the filament. Consult the filament’s manufacturer specifications. Typically, PLA performs best at 50-60°C, while ABS requires temperatures around 100-110°C. Maintain a stable bed temperature throughout the print for consistent results. This temperature will change based on the filament.

Adjusting First Layer Height

The first layer height determines the thickness of the initial layer. Correct adjustment is critical for bed adhesion and print quality. If the first layer is too thin, it won’t stick to the bed. If it’s too thick, it can cause nozzle clogging or poor surface finish. Start with the manufacturer’s recommended settings. Then, fine-tune the first layer height in small increments. Aim for a slightly squished first layer. This promotes strong adhesion and a smooth initial surface.

Avoiding Common Pitfalls

Avoiding common pitfalls can help ensure smooth and successful prints. Being aware of these potential problems will save time and filament. Proactive troubleshooting enables users to identify and resolve issues quickly. Addressing these common mistakes improves print quality and the overall 3D printing experience.

Preventing Warping

Warping is a common issue. It occurs when the corners of the print lift off the bed during printing. It is caused by uneven cooling. To prevent warping, ensure the bed is level. Use an appropriate bed adhesive. Use a brim or raft. These techniques can help the print adhere better to the bed and reduce warping. Enclosing the printer can also help to maintain a stable temperature and prevent warping, especially for ABS and other materials prone to this issue.

Dealing with Nozzle Issues

Nozzle issues, such as clogging or improper height, are common causes of poor print quality. Regularly inspect your nozzle for clogs. Ensure it is clean and clear. Adjust the nozzle height correctly to ensure proper filament extrusion. If the nozzle is too close to the bed, it can scrape the filament. If the nozzle is too far, the filament will not adhere. Replace the nozzle if it is damaged. Correct maintenance and calibration will prevent many nozzle-related problems. This greatly improves print quality and the printing process.

By understanding and addressing these issues, you can significantly improve the smoothness of your Tevo Tarantula’s bed and achieve high-quality prints. Proper bed leveling, adhesion, and parameter optimization are key to a successful 3D printing experience. Following these steps will ensure the printer runs optimally.