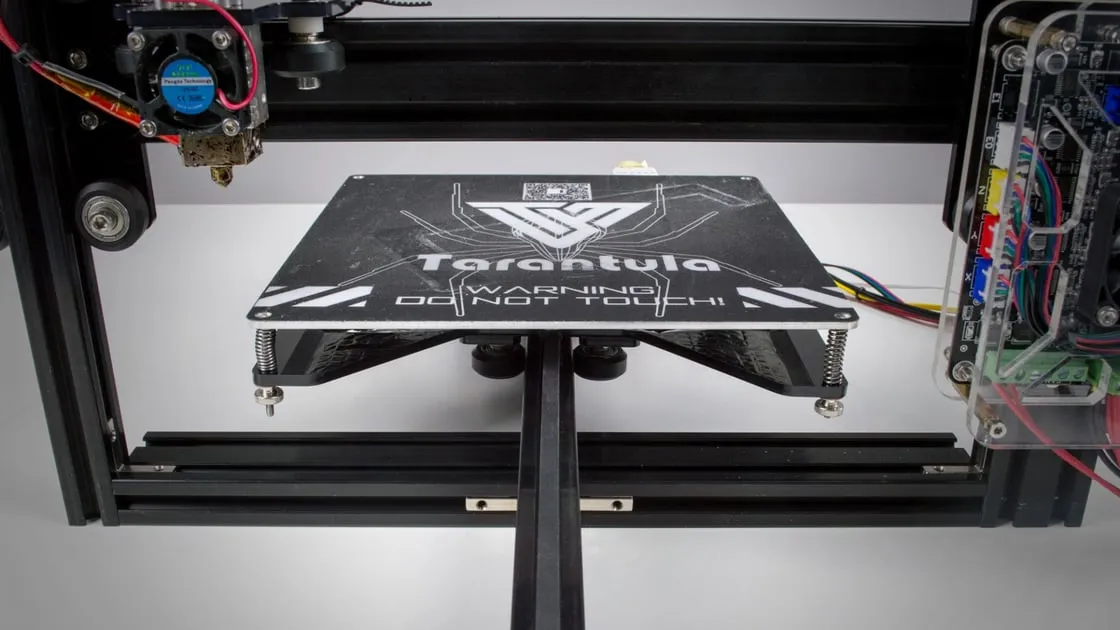

Why Upgrade to a Tevo Tarantula Magnetic Bed

Upgrading your Tevo Tarantula 3D printer with a magnetic bed is a game-changer for both beginners and experienced makers. This modification significantly enhances the 3D printing experience, offering several advantages over the standard print bed. A magnetic bed provides a more user-friendly and efficient way to manage your prints. This guide will walk you through the benefits, selection process, and installation steps to help you make the most of your Tevo Tarantula and achieve high-quality 3D prints with ease. From improved adhesion to simplified print removal, the advantages are numerous. Let’s dive in and explore how a magnetic bed can transform your 3D printing journey.

Benefits of a Magnetic Bed for 3D Printing

The transition to a magnetic bed for your Tevo Tarantula brings a suite of benefits that streamline the printing process and improve overall print quality. These advantages range from ease of use to better print outcomes, making it a worthwhile upgrade for any 3D printing enthusiast. The most significant improvements are observed during the critical stages of print adhesion and removal.

Improved Adhesion

Magnetic beds, when used with the right build surface, often provide superior adhesion compared to the stock bed. This enhanced grip is crucial during the initial layers, preventing warping and ensuring the print stays firmly in place throughout the process. The magnetic base holds the build plate securely, and the build surface material, whether PEI, BuildTak, or another type, provides an excellent surface for the filament to bond to. This strong bond minimizes the risk of print failures due to detachment during printing, leading to more successful prints. Furthermore, improved adhesion allows for printing with a wider range of filaments, including those that are prone to warping, like ABS.

Ease of Removal

One of the most appreciated benefits is the ease of print removal. With a magnetic bed, you can simply flex the build plate to pop off your finished prints. No more scraping and potential damage to your prints or the bed surface. This feature saves time and reduces the risk of damaging the print bed. The flexible surface allows for a clean and effortless removal process, preserving both your prints and the bed’s longevity. This also makes post-processing much easier, as you can quickly detach the print without the need for tools or excessive force.

Enhanced Print Quality

The improved adhesion and bed stability contribute to better print quality. The magnetic bed ensures a consistently flat surface, crucial for the first layer’s accuracy. This consistency results in well-defined details and dimensional accuracy. Furthermore, the reduced risk of warping and detachment during the printing process leads to a higher success rate of high-quality prints. This is especially noticeable with larger prints or those using materials that are prone to warping. With a magnetic bed, you’ll spend less time troubleshooting and more time creating.

Choosing the Right Magnetic Bed for Your Tevo Tarantula

Selecting the correct magnetic bed involves considering various factors to ensure compatibility, performance, and durability. There are several types of magnetic beds available, each with different features and materials. Understanding these options helps you make an informed decision that suits your printing needs and preferences. Think about the size, the type of build surface, and the quality of the materials used. Consider your filament types and your priorities when choosing your magnetic bed.

Types of Magnetic Beds

Magnetic beds typically consist of two parts a magnetic base that attaches to the printer’s bed and a flexible build surface. The build surface is what your prints adhere to. The most common types include those with a PEI (Polyetherimide) surface, which offers excellent adhesion and is known for its durability, and those with BuildTak or similar adhesive surfaces. PEI surfaces are generally preferred for their ease of use and versatility with different filaments. BuildTak-like surfaces provide a reliable bond but may require more careful handling. Other options may include magnetic beds with pre-applied adhesive sheets. Consider your preferred method of print removal and filament types when choosing the type of magnetic bed.

Flexible Build Surfaces

Flexible build surfaces are a crucial part of the magnetic bed system. They are designed to be removed from the magnetic base and flexed to release the printed object. PEI sheets are a popular choice for their excellent adhesion and ease of use. BuildTak-like surfaces are also effective. These surfaces offer a balance of adhesion and release properties that are suitable for a variety of filaments. They must withstand the rigors of the printing process, including high temperatures and frequent flexing. Look for a build surface that is resistant to wear and tear and easy to clean. The ability to quickly remove prints without tools is one of the key benefits of this system.

Bed Size and Compatibility

Ensure that the magnetic bed is compatible with your Tevo Tarantula’s bed size. Measure your existing bed to confirm the dimensions and choose a magnetic bed that fits. Some magnetic beds are designed to be a direct replacement, while others may require minor adjustments. Compatibility is essential for proper installation and functionality. Check the product specifications to confirm that it is suitable for the Tevo Tarantula. Consider the available space on your printer’s bed and the size of the prints you typically create. A well-fitting magnetic bed ensures optimal performance and ease of use.

Materials and Durability

Pay attention to the quality of materials used in the magnetic bed. High-quality magnetic bases should provide strong adhesion. The build surface should be made of durable materials that can withstand repeated use and high temperatures. PEI sheets are known for their durability and resistance to warping. The magnetic base should be able to withstand the heat generated during the printing process. Choose a magnetic bed made of materials that can withstand the rigors of 3D printing. A durable magnetic bed will offer longevity and reliable performance, giving you better value for your investment.

Step-by-Step Installation Guide

Installing a magnetic bed on your Tevo Tarantula is a straightforward process. Following these steps will ensure a smooth and successful installation. With the right preparation, you can quickly upgrade your printer and enjoy the benefits of a magnetic bed. It’s a relatively simple process, and the improved performance is well worth the effort. Ensure that you take the necessary safety precautions before you begin.

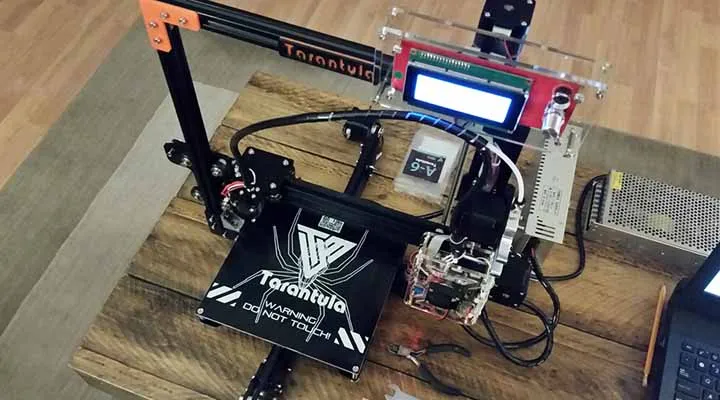

Gathering Your Materials

Before you start, gather all the necessary materials. You will need the magnetic bed kit, which includes the magnetic base and the build surface. Ensure that you have the correct tools, such as a screwdriver or Allen key, to remove and secure the existing bed and install the magnetic base. It’s advisable to have a level handy for the initial bed leveling process. Clear the work area and ensure that you have everything needed before beginning the installation to prevent any interruptions.

Preparing the Tevo Tarantula Bed

Turn off and unplug your Tevo Tarantula. Remove the existing print bed. This might involve unscrewing it from the frame. Clean the printer bed frame to ensure a clean surface for the magnetic base. Make sure the area is free of any debris or obstructions. This step is crucial for proper adhesion of the magnetic base to the printer frame, so take your time to prepare the frame correctly.

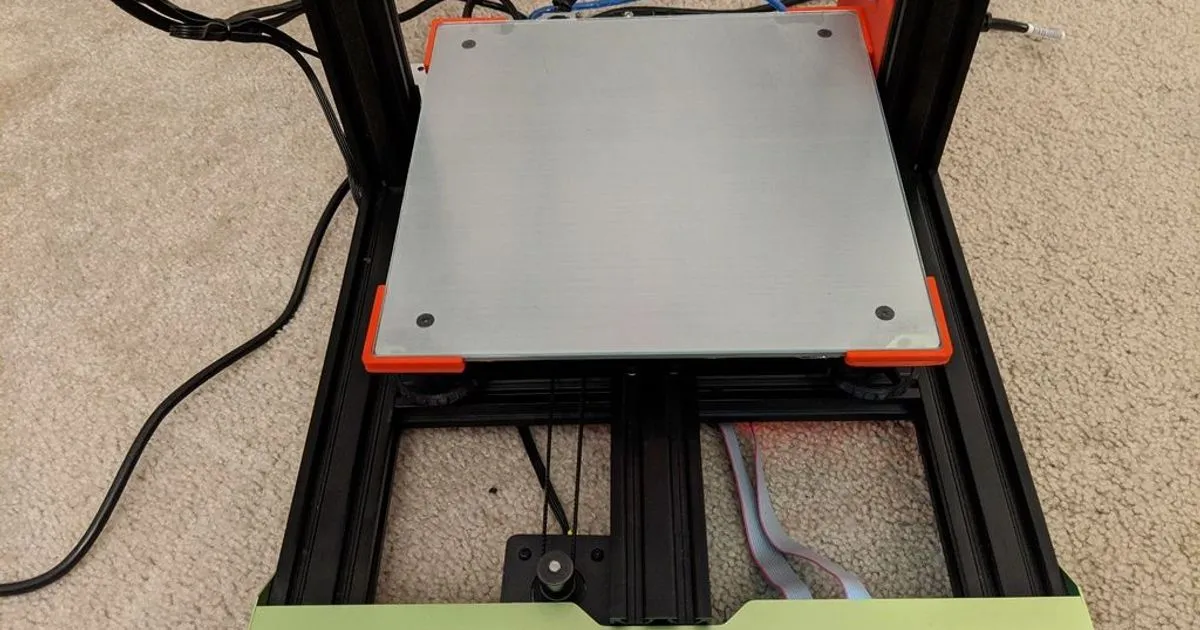

Attaching the Magnetic Base

Carefully align and attach the magnetic base to the Tevo Tarantula’s bed frame. The magnetic base typically has an adhesive backing or uses screws for attachment. If it has an adhesive backing, carefully peel off the protective layer and stick the base onto the bed frame, ensuring it is centered. If using screws, make sure to secure the base properly to the frame. The magnetic base must be firmly attached to provide a stable surface for the build plate. Ensure that there are no air bubbles or gaps between the base and the frame for optimal performance.

Securing the Build Surface

Once the magnetic base is in place, carefully attach the build surface. The build surface should align perfectly with the magnetic base. Ensure that the surface is flat and free of any debris. Make sure the build surface is securely attached to the magnetic base. After attaching the surface, you can start the calibration and leveling process. It should easily attach to the magnetic base and provide a clean and reliable surface for your prints. Properly securing the build surface will help improve print quality.

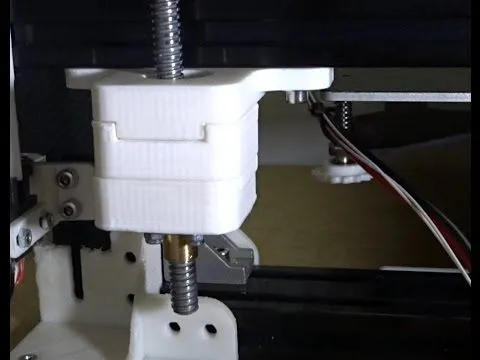

Calibration and Leveling

Calibration and leveling are critical steps after installing your new magnetic bed. A properly leveled bed ensures that the first layer adheres correctly and that your prints are successful. The process might need some adjustments to achieve optimal results. The initial calibration and adjustment of the Z-offset are vital for successful printing.

Initial Bed Leveling

Start by leveling the bed using your printer’s leveling procedure. Most 3D printers have a manual or automatic bed leveling system. Use the leveling screws or the automatic leveling feature to ensure the bed is level in relation to the nozzle. The nozzle should be at a consistent distance from the bed at all points. Accurate leveling is crucial for the first layer to stick properly. Repeat this procedure until the bed is level across all points.

Fine-tuning the Z-offset

The Z-offset is the distance between the nozzle and the build surface when the printer homes. Fine-tuning the Z-offset is essential to achieving a perfect first layer. You can typically adjust the Z-offset in your printer’s settings. Test your first layer by printing a small test print, such as a square or a line. Adjust the Z-offset up or down based on the print quality. The goal is to achieve a layer that is slightly squished but not too much to prevent clogging or detachment. Make several adjustments until you get the perfect first layer.

Optimizing Print Settings for Magnetic Beds

Optimizing your print settings can further enhance the performance of your magnetic bed. The adjustments to temperature and first-layer adhesion techniques are critical for successful prints. Fine-tuning these settings will help you achieve the best possible results. Understanding these settings will enable you to get the most out of your magnetic bed setup.

Bed Temperature Adjustments

Adjust the bed temperature to suit the filament you are using. Different filaments require different bed temperatures for optimal adhesion. Refer to the filament manufacturer’s recommendations. For example, PLA typically benefits from a bed temperature of 50-60°C, while ABS may require 100-110°C. Using the correct bed temperature will help ensure the first layer sticks to the build surface. Avoid excessive bed temperatures to prevent warping. Adjust the temperature settings for each material you use to guarantee the best results.

First Layer Adhesion Techniques

Using the right first-layer adhesion techniques will enhance the success of your prints. Adjust your nozzle height and flow rate to ensure proper adhesion. Applying a thin layer of adhesive, such as glue stick or hairspray, can improve adhesion. Using a brim or raft can also help to secure the first layer. Proper techniques will provide a better foundation for the prints, leading to more successful outcomes. Experiment with different settings and techniques to determine what works best for your printer and materials.

Troubleshooting Common Issues

Even with the best setup, you might encounter some issues. Common problems include poor adhesion, warping, and bed leveling problems. Understanding these issues and the solutions will help you troubleshoot your prints. Learning how to solve these common problems ensures you can achieve successful prints every time. The most important thing is to understand the issue and find a solution.

Poor Adhesion

If your prints are not sticking to the bed, review your bed leveling and Z-offset settings. Ensure the bed is level and the nozzle height is correct. Check your bed temperature, and adjust it according to the filament you are using. Clean the build surface with isopropyl alcohol to remove any residues. Consider applying an adhesive, such as glue stick or hairspray. Adjusting these aspects will improve adhesion and provide a solid base for your prints.

Warping

Warping is a common problem, especially with filaments such as ABS. Ensure the bed temperature is appropriate. Use an enclosure to maintain a consistent temperature around the print. Apply a brim or raft to the first layer to provide extra adhesion. Reducing the bed temperature or using an enclosure can help prevent warping. Preventing warping can guarantee the correct dimensions and prevent print failure.

Bed Leveling Problems

If you’re having bed leveling problems, re-level the bed, and make sure the Z-offset is correctly adjusted. Check for any physical obstructions that might be preventing the bed from leveling properly. Ensure the bed is stable. Troubleshoot any mechanical issues on your printer that could be interfering with the leveling process. Proper bed leveling is the base for the rest of your printing tasks.

Maintaining Your Magnetic Bed

Regular maintenance will keep your magnetic bed in optimal condition. The following procedures will prolong the life of your magnetic bed. Taking good care of your bed will ensure it lasts for a long time. Keep your bed in good condition with these maintenance tips.

Cleaning Your Build Surface

Clean your build surface regularly with isopropyl alcohol or a similar cleaning agent. This will remove any residues and improve adhesion. Make sure to do this before each print. Clean the build surface frequently to improve your print success. A clean surface leads to better adhesion and reduces the chances of print failure.

Checking for Wear and Tear

Inspect your magnetic bed for any signs of wear and tear. Check the build surface for scratches or damage. Replace the build surface if necessary. Check the magnetic base to see that it’s still firmly attached to the bed frame. Regular checks will prevent any problems and maintain consistent performance. Regular maintenance will help extend the life of your bed.