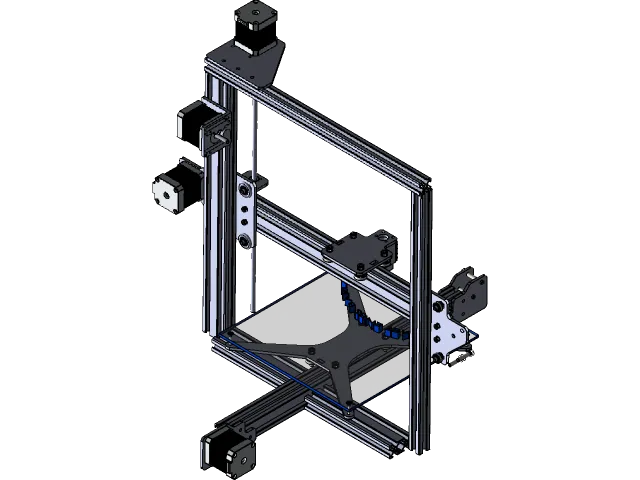

Understanding Tevo Tarantula Under Extrusion

Under extrusion is a common problem faced by Tevo Tarantula 3D printer users, resulting in prints with weak layers, gaps, or incomplete sections. This issue arises when the printer fails to push out the correct amount of filament during the printing process. Identifying and fixing under extrusion is crucial for achieving high-quality 3D prints. This guide will help you understand the causes and solutions for under extrusion with your Tevo Tarantula, ensuring your prints are strong and accurate. The first step is understanding what causes this issue so you can start troubleshooting and fixing the problem. Let’s get started on creating perfect prints!

What is Under Extrusion

Under extrusion occurs when the 3D printer doesn’t extrude the correct amount of filament required for each layer of the print. This deficiency leads to visible gaps, weak layer adhesion, and an overall reduction in the structural integrity of the printed object. The symptoms of under extrusion can vary. Prints may have missing sections, inconsistent layer lines, or a generally rough surface finish. Recognizing these signs is vital for diagnosing and addressing the issue. Correcting under extrusion is vital for getting successful 3D prints, as it directly impacts the quality and functionality of your 3D models. The goal is to create prints with smooth, solid layers that bond correctly to create your desired 3D print.

Common Causes of Under Extrusion

Several factors can contribute to under extrusion in your Tevo Tarantula. Addressing these issues requires systematic troubleshooting. Filament, nozzle, temperature, and mechanical issues are among the most frequent culprits. Understanding these causes is the initial step towards resolving under extrusion and restoring your printer’s performance.

Filament Issues

The filament itself can be a primary cause. Issues include the filament diameter not matching printer settings, which can lead to under extrusion. Poor-quality filament often contains impurities or inconsistencies that cause it to extrude unevenly, leading to under extrusion. Using filament that has absorbed moisture from the environment will also result in under extrusion as the moisture turns to steam in the nozzle, causing inconsistent extrusion. Inspect your filament carefully for any irregularities, store it in a dry place, and ensure your printer settings match the filament specifications. Consider these items when troubleshooting your 3D printing problems to ensure success.

Nozzle Problems

Nozzle obstructions are a common culprit. Clogs prevent the filament from flowing smoothly, causing under extrusion. The nozzle tip’s wear and tear can also affect extrusion quality. Over time, the nozzle can widen or become damaged, leading to inconsistent extrusion. To combat this problem, regular nozzle maintenance, cleaning, and the use of appropriate nozzle materials are essential. You can also try replacing the nozzle entirely with a new one and see if this solves the issue. This is a common and easy fix for under extrusion problems.

Temperature Settings

Incorrect temperature settings are a key cause of under extrusion. If the nozzle temperature is too low, the filament won’t melt sufficiently to flow properly, leading to under extrusion. Conversely, if the temperature is too high, the filament can degrade or become runny, leading to other print defects. To troubleshoot, consult the filament manufacturer’s recommendations for optimal printing temperatures and use this as a guide for your prints. Calibrating the temperature settings to match the specific filament type is a must. Always adjust these settings gradually to optimize the extrusion quality and create the perfect print.

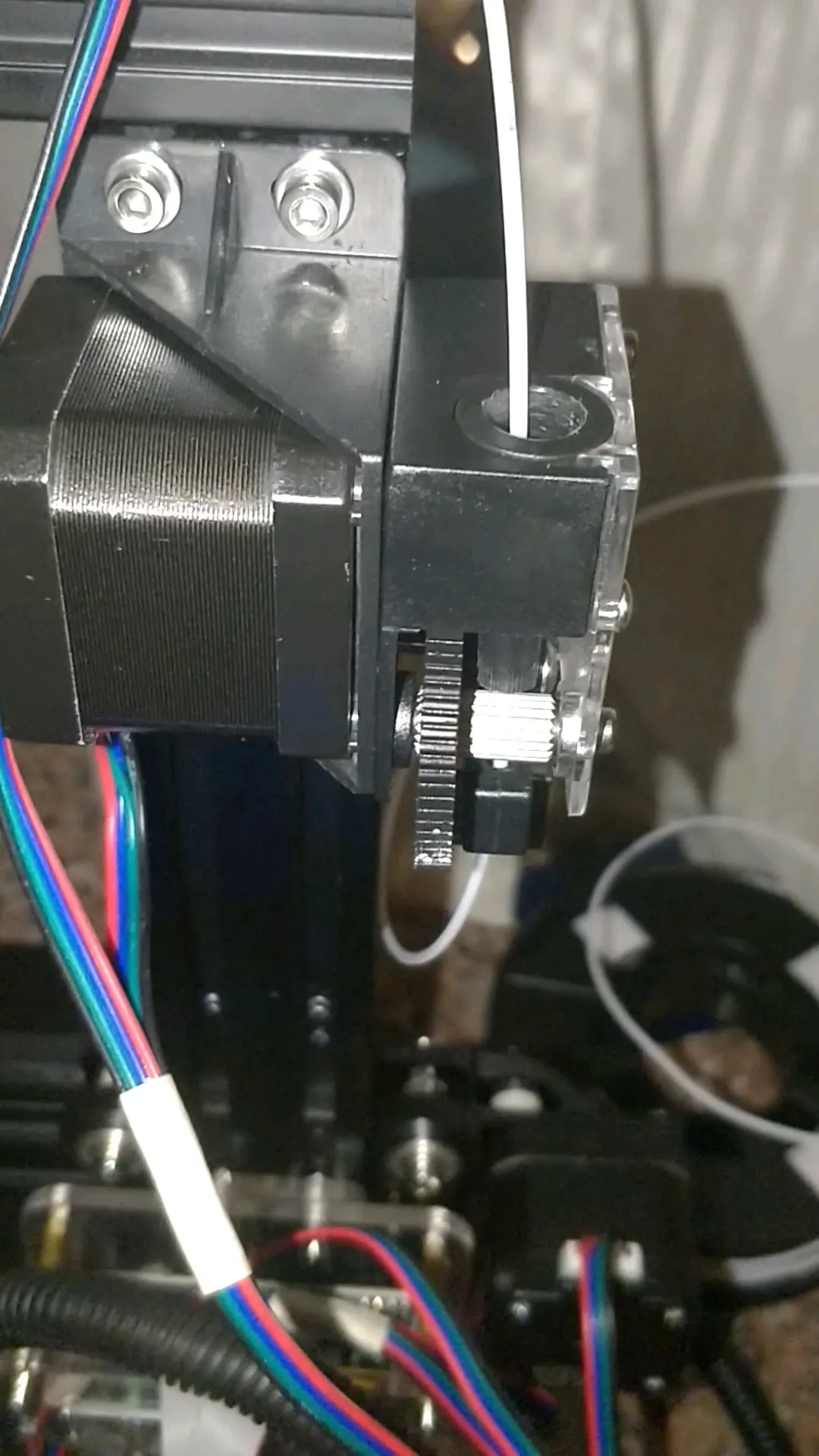

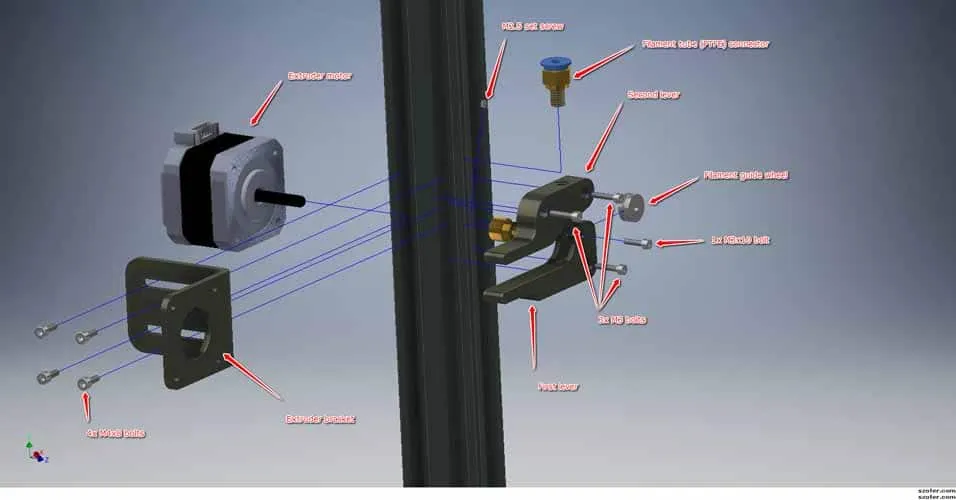

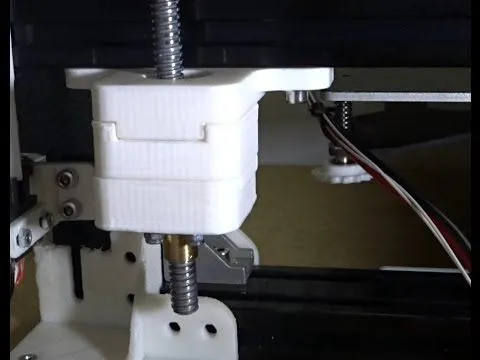

Mechanical Issues

Mechanical problems can disrupt the filament flow. Problems such as a loose extruder gear might not grip the filament effectively, which leads to under extrusion. The extruder gear can also get worn down with use, which prevents the filament from being pushed at a consistent rate. Another key factor is the extruder motor; if it’s not providing enough torque, it will not be able to push the filament, causing under extrusion. Ensure all mechanical components are clean, properly adjusted, and in good working order to ensure consistent extrusion.

How to Fix Tevo Tarantula Under Extrusion

Resolving under extrusion requires a methodical approach, addressing the root causes. This can involve troubleshooting filament issues, nozzle maintenance, temperature adjustments, and mechanical calibrations. By systematically checking each area, you can diagnose and fix the problem. Begin by carefully examining your printer settings and the physical components involved in the printing process. Correcting under extrusion will substantially enhance print quality, giving you more successful prints. Let’s begin solving this issue by following these steps.

Filament Troubleshooting

Troubleshooting the filament is a critical first step. Begin by inspecting the filament for any physical defects or inconsistencies. Check that the filament diameter matches your printer’s settings. Confirm that the filament is not tangled or caught on something which could prevent it from feeding correctly. These are all quick checks that you can do before printing, to prevent the issue. Use these tips to ensure that the filament is in the best condition to create excellent prints.

Selecting the Right Filament

Choosing the right filament is critical for good print quality. Always use high-quality filament from a reputable supplier. Verify the filament specifications, paying attention to the material type, diameter, and recommended printing temperatures. Ensure the filament suits the type of model you are printing. Consider the filament’s properties such as its flexibility and strength; these factors significantly affect print results. If possible, try to print a small test object with different filaments to determine which one performs best. This is a good way to see what works best for you and your printer.

Proper Filament Storage

Proper storage is another key to successful printing. Filament that has absorbed moisture will cause under extrusion. Store filament in a dry environment, away from direct sunlight and humidity. Consider using airtight containers or desiccant packs to reduce moisture absorption, especially in humid climates. If you live in a high-humidity environment, drying your filament before use can further improve print quality. By following these steps, you will greatly increase the chances of good quality 3D prints with your Tevo Tarantula printer.

Nozzle Cleaning and Replacement

Nozzle maintenance is essential for preventing under extrusion. Clogged nozzles are a frequent cause, so it’s important to address them promptly. Proper cleaning and replacement of the nozzle will help to solve the problem. Regular maintenance of the nozzle will help to ensure that your prints come out as desired.

Cleaning the Nozzle

Regularly clean the nozzle to remove any material build-up. The easiest method involves heating the nozzle to the appropriate temperature and then using a needle or a specialized cleaning tool to remove any obstructions. Another method is doing a ‘cold pull’ where you heat the nozzle, manually extrude some filament, then cool the nozzle down, and pull the filament out, taking any debris along with it. Always be careful not to damage the nozzle during the cleaning process. Ensuring your nozzle is clean is a quick fix for under extrusion problems.

Replacing the Nozzle

Sometimes, a nozzle may be too damaged or worn to be fixed by cleaning. In this case, replacing the nozzle is the best option. Replacement is a relatively simple procedure: heat the nozzle to the appropriate temperature, carefully unscrew the old nozzle, and screw in a new one. Be sure to tighten the new nozzle securely to avoid leaks. By regularly checking and replacing the nozzle, you can fix one of the most common causes of under extrusion. This simple step will ensure that your printer can consistently print properly.

Temperature Calibration

Temperature calibration is critical. The correct temperature settings are vital for ensuring the filament melts and extrudes properly. Adjusting the temperature appropriately will reduce the likelihood of under extrusion. Always consult the filament manufacturer’s recommended printing temperatures as a guide. A temperature calibration tower can be a good option to determine the optimal temperature for your printer.

Adjusting Printing Temperature

Start by experimenting with the recommended temperature range for your filament. Increase the temperature in small increments until you get good extrusion without any signs of overheating. Remember to adjust the bed temperature for optimal adhesion. Be patient and make incremental changes. Keep a close eye on the first layers of the print as you test the new temperatures. When you start seeing good adhesion and smooth layers, you will know you found the ideal setting. This will result in great prints!

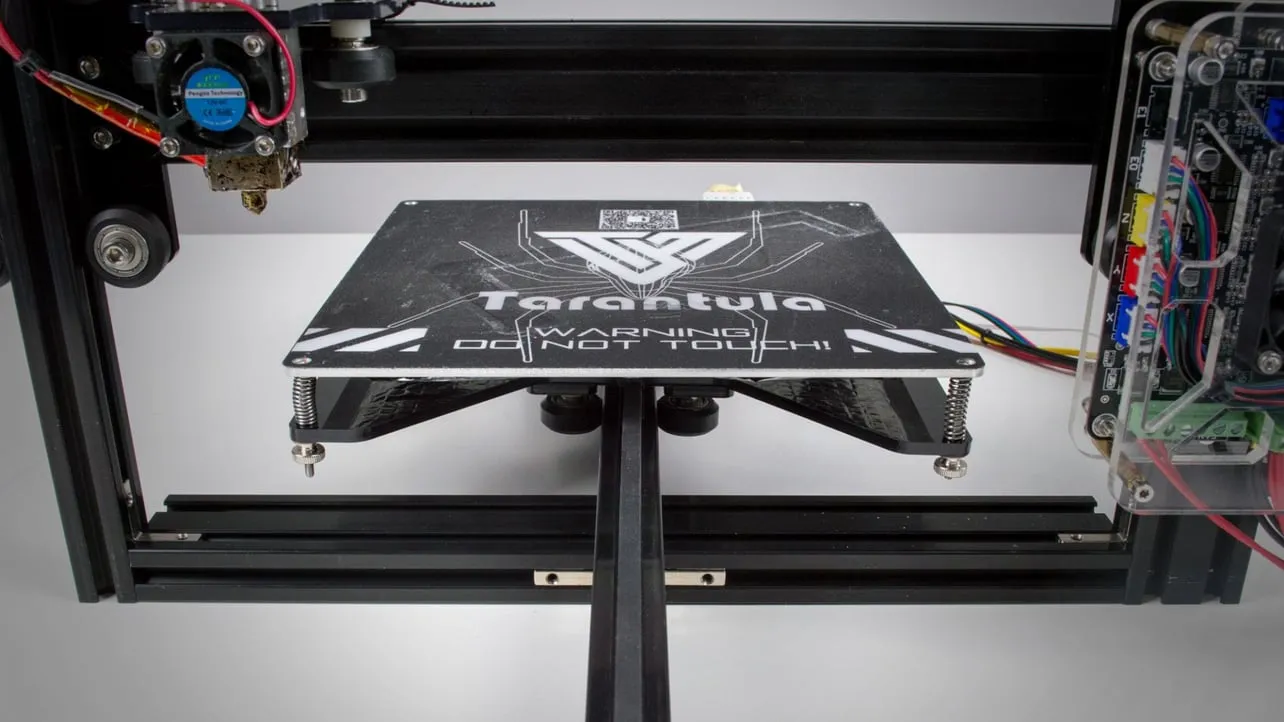

Bed Adhesion

Good bed adhesion is crucial for preventing warping and other print issues. Ensure your print bed is level and clean. Use bed adhesion aids like glue stick or painter’s tape if needed. The appropriate bed temperature is critical for different filament types. Proper bed adhesion helps stabilize the first layers, improving the overall print quality. When your bed is level and has good adhesion, you will have a greater chance of printing great models.

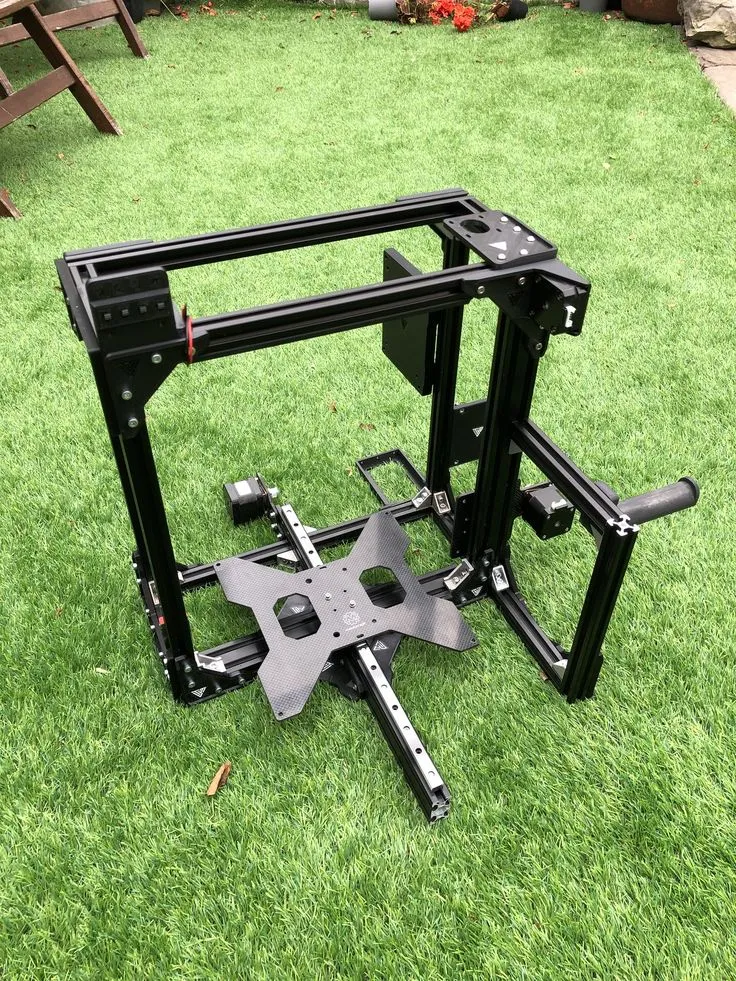

Mechanical Adjustments

Check the printer’s mechanical components for any issues. Loose belts and worn extruder gears can contribute to under extrusion. Addressing these mechanical problems will improve the performance of your printer and result in good print quality.

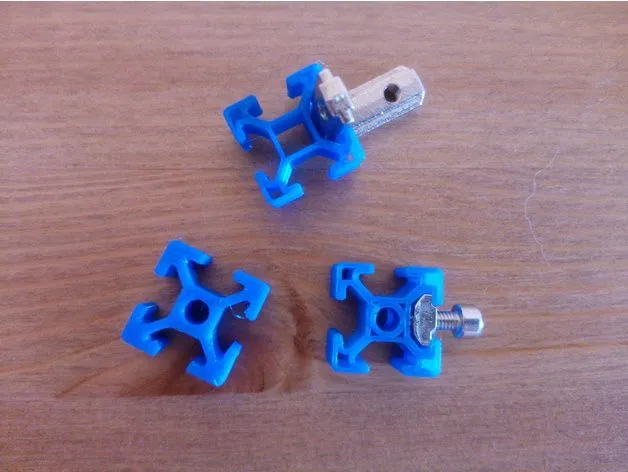

Checking the Extruder Gear

Check the extruder gear for wear and tear. This gear pushes the filament into the hot end. Make sure the gear teeth are clean and in good condition. If the gear is worn, replace it, so it can grip the filament correctly. Ensure the extruder gear is properly aligned and secured to avoid any slippage. Examine the gear to be sure that it is able to push the filament at the correct rate.

Belt Tension

Check belt tension regularly, as loose belts can cause printing issues. Tighten the belts appropriately, ensuring there is no slack but not over-tightening them. Properly tensioned belts ensure that the printer moves accurately, which is crucial for good extrusion. Consistent belt tension results in more accurate prints. If you find that the belts are loose, tighten them by adjusting the tensioners on the printer.

Conclusion

Under extrusion can be frustrating. Addressing and fixing it will significantly improve the quality of your 3D prints. By understanding the common causes of under extrusion and following the troubleshooting steps outlined in this guide, you can resolve this issue. Remember to regularly maintain your Tevo Tarantula, check and adjust your settings as needed, and experiment with different filament types to find what works best. With patience and attention to detail, you can achieve perfect prints every time and fully enjoy your 3D printing experience.