Understanding Z-Axis Calibration on Tevo Tarantula

Calibrating the Z-axis on your Tevo Tarantula is a fundamental step towards achieving high-quality 3D prints. The Z-axis controls the vertical movement of the print head, dictating the distance between the nozzle and the print bed. Proper calibration ensures that the first layer of your print adheres correctly, preventing warping and other print defects. This guide will walk you through the necessary steps to get your Tevo Tarantula printing flawlessly. Accuracy in Z-axis calibration directly affects the overall print quality, dimensional accuracy, and the success of your 3D printing endeavors. Without it, you’ll likely experience inconsistent layer adhesion, poor surface finish, and potential print failures.

The Importance of Z-Axis Calibration

Accurate Z-axis calibration is crucial for several reasons. It ensures that the first layer of your print adheres properly to the print bed. If the nozzle is too far from the bed, the filament won’t stick, and the print will fail. If the nozzle is too close, it can scrape the bed, damage the nozzle, or prevent the filament from extruding correctly. Furthermore, proper calibration is essential for dimensional accuracy. The Z-axis controls the height of each layer, so any inaccuracies will propagate throughout the entire print. This can lead to parts that don’t fit together correctly or have incorrect dimensions. Good calibration also prevents common issues like elephant’s foot and poor layer adhesion.

Common Issues with Incorrect Z-Axis Calibration

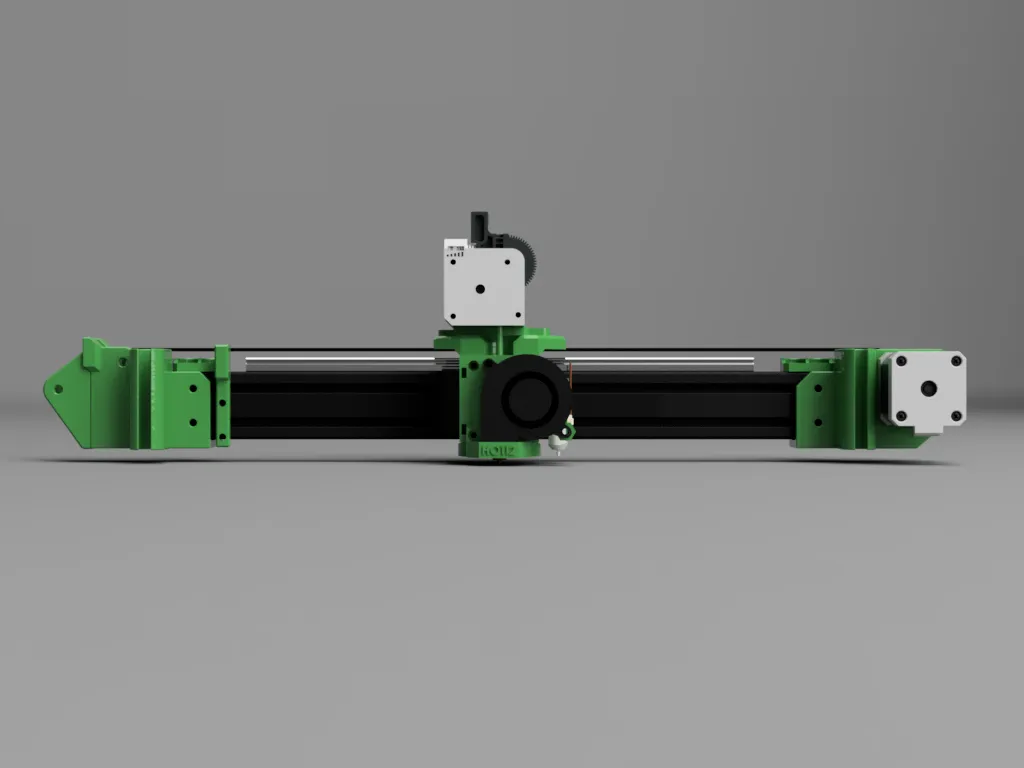

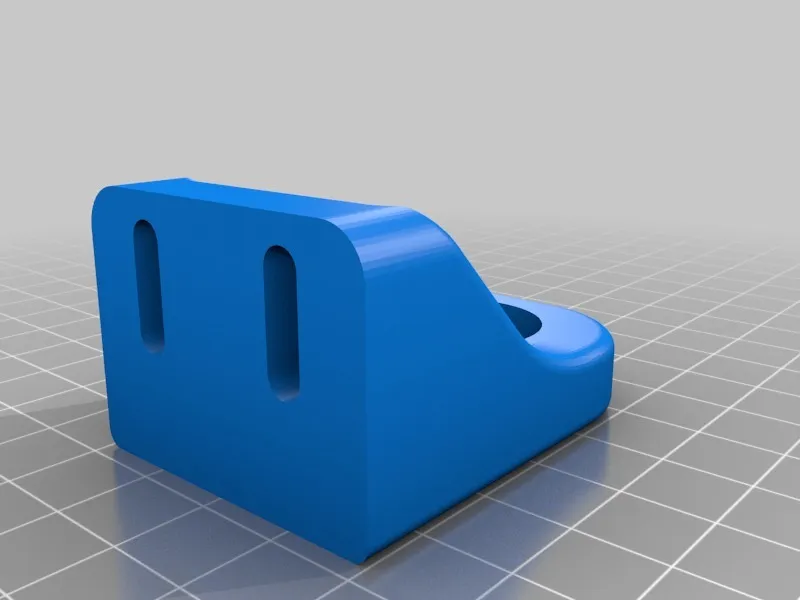

Incorrect Z-axis calibration manifests in various ways. One of the most common issues is the failure of the first layer to adhere to the print bed. The filament may not stick, resulting in a tangled mess of plastic. Another problem is the ’elephant’s foot’ effect, where the bottom layers of the print bulge outwards due to the nozzle being too close to the bed. Warping, where the edges of the print curl upwards, is another sign of poor calibration, often caused by the nozzle being too far from the bed. You might also notice poor layer adhesion, where the layers don’t stick together properly, leading to weak prints that easily break apart. These issues highlight the importance of meticulous calibration for optimal print results. See image tevo-tarantula-z-axis-calibration-1.webp.

Tools You’ll Need

Before starting the calibration process, gather the necessary tools to ensure a smooth and accurate setup. Having the right equipment will streamline the process and improve your chances of success. The following are essential tools you’ll need to perform the Z-axis calibration on your Tevo Tarantula. Proper preparation is key to a successful calibration process, and having the right tools is the first step.

Essential Tools for Calibration

You’ll need a few essential tools for calibrating the Z-axis. First, you’ll need a piece of paper, preferably standard printer paper, to use as a feeler gauge. You will use this to determine the distance between the nozzle and the print bed. Secondly, you’ll need the tools that came with your Tevo Tarantula, specifically the Allen wrenches for adjusting the bed leveling screws and the Z-axis endstop. A ruler or calipers can be helpful for measuring the distance between the nozzle and the bed, though not strictly required. It’s also useful to have some filament loaded in your printer, so you can easily test the calibration by printing a small test object or a first-layer test. Having a small screwdriver can also be useful. See image tevo-tarantula-z-axis-calibration-2.webp.

Step-by-Step Z-Axis Calibration Guide

Now, let’s walk through the step-by-step process of calibrating the Z-axis on your Tevo Tarantula. This guide breaks down the process into manageable steps, ensuring you achieve accurate and consistent results. Following these steps meticulously will significantly improve your print quality and reduce common printing issues. Remember to take your time and double-check each step. Patience is key to this process.

Preparation and Safety

Before you begin, make sure your Tevo Tarantula is powered off and unplugged. Safety first! Ensure that the print bed is clear of any debris or old filament. Check that your hot end is also clear of any residue. Place the printer on a stable surface to prevent any movement during calibration. Double-check that your bed leveling screws are accessible and that you have all the necessary tools at hand. Preparing your printer properly ensures a safe and efficient calibration process.

Leveling the Bed

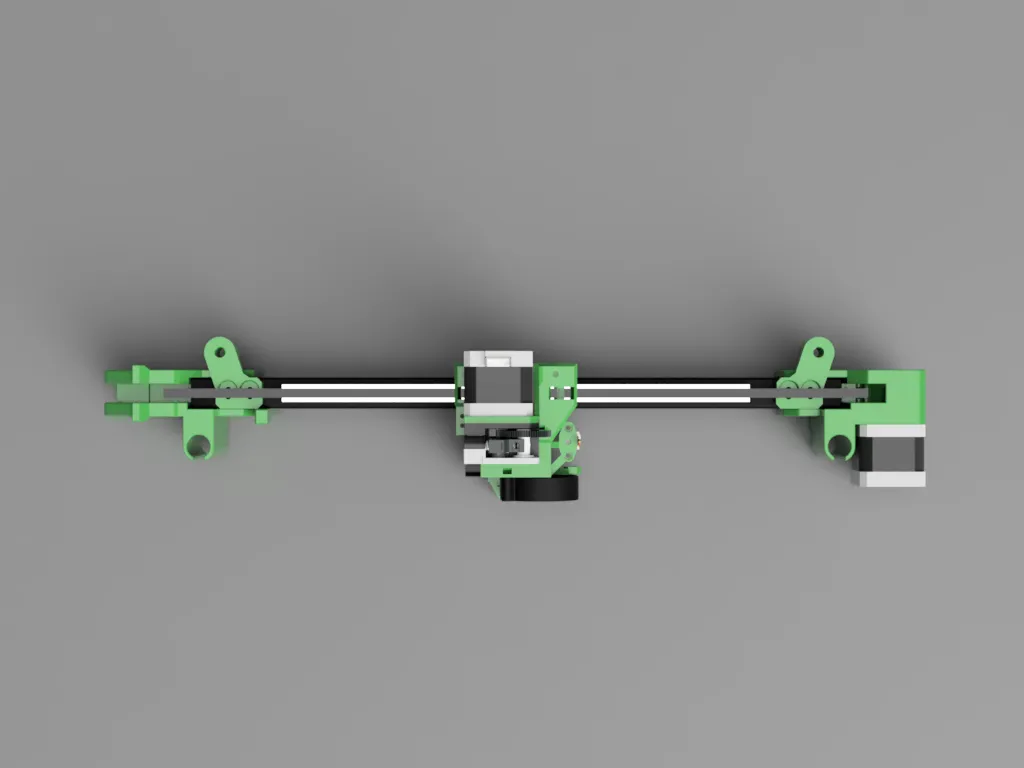

Bed leveling is the foundation for accurate Z-axis calibration. Use the leveling screws located under the print bed to adjust the bed height at each corner. Move the print head to each corner of the bed and use the paper feeler gauge to determine the distance between the nozzle and the bed. Adjust the bed leveling screws until the nozzle lightly grips the paper as you slide it. The paper should have slight resistance, but you should still be able to move it. Repeat this process for all four corners, ensuring the bed is as level as possible. See image tevo-tarantula-z-axis-calibration-3.webp.

Adjusting the Z-Axis Endstop

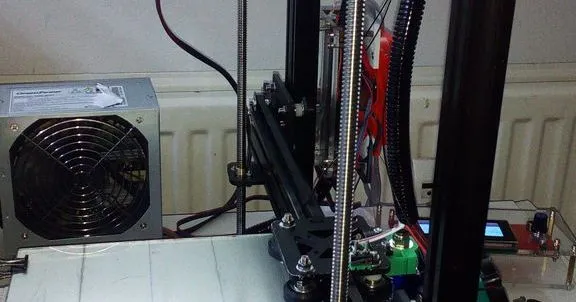

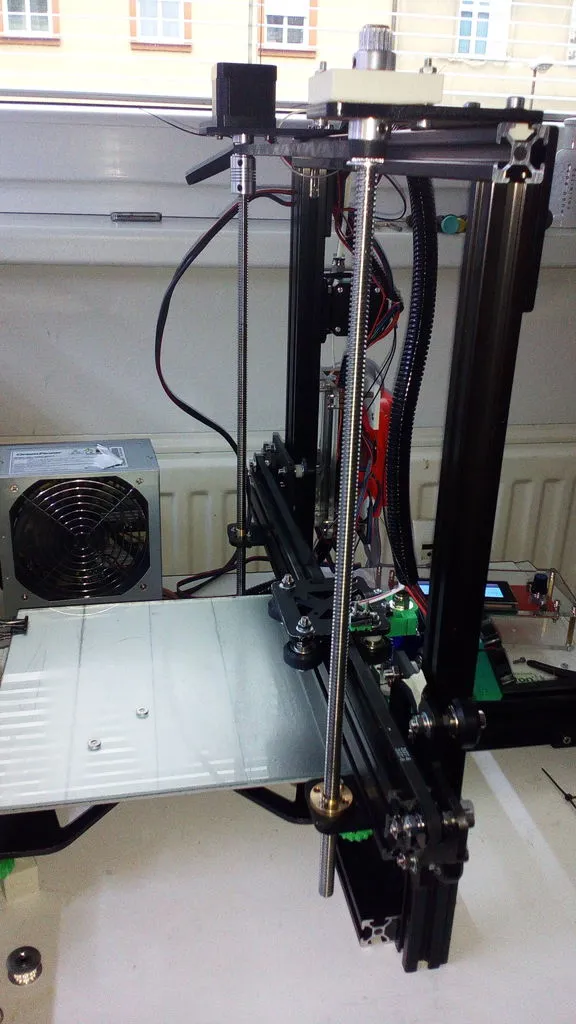

The Z-axis endstop tells the printer when the nozzle is at the Z=0 position. Locate the Z-axis endstop on your Tevo Tarantula. It’s usually a small switch or sensor that triggers when the print head reaches a certain height. Loosen the screws holding the endstop in place. Move the print head to the center of the bed and lower it until the nozzle almost touches the bed. Place the paper feeler gauge between the nozzle and the bed. Adjust the Z-axis endstop up or down until the nozzle gently touches the paper. Tighten the screws to secure the endstop. See image tevo-tarantula-z-axis-calibration-4.webp.

Fine-Tuning the Z-Offset

The Z-offset fine-tunes the distance between the nozzle and the bed during printing. Most 3D printers have a setting in their firmware or on the control panel to adjust the Z-offset. After leveling the bed and adjusting the endstop, heat the nozzle and bed to your typical printing temperatures. Start a print, preferably a first-layer test print. While the first layer is printing, adjust the Z-offset in small increments. If the nozzle is too far from the bed, the filament won’t stick. If it’s too close, the nozzle will scrape the bed. Adjust the offset until you get a nice, even first layer with good adhesion. This might take a few adjustments. See image tevo-tarantula-z-axis-calibration-5.webp.

Testing the Calibration

After adjusting the Z-offset, it’s time to test your calibration. Print a small test object, such as a first-layer test or a small square. Observe the first layer closely. It should be smooth, even, and well-adhered to the bed. If the first layer looks good, you can proceed with printing more complex objects. If you notice any issues, such as poor adhesion or uneven layers, re-evaluate your calibration and make further adjustments to the Z-offset or bed leveling. Keep testing until your prints are consistently coming out well. Also, print test on different areas to ensure consistency. See image tevo-tarantula-z-axis-calibration-6.webp.

Troubleshooting Common Problems

Even with careful calibration, you might encounter some issues. Here are some common problems and their solutions. Identifying these problems and understanding their causes will help you troubleshoot and achieve better print results.

Nozzle Too Far from Bed

If the nozzle is too far from the bed, the filament won’t stick. You’ll see gaps between the lines of the first layer. The solution is to lower the Z-offset or re-level the bed. Increase the Z-offset in small increments until the filament begins to adhere properly. Ensure the bed is level across all corners. See image tevo-tarantula-z-axis-calibration-7.webp.

Nozzle Too Close to Bed

If the nozzle is too close to the bed, the filament will be squished. You might see lines of filament that are too thin, and the nozzle might scrape the bed. The solution is to raise the Z-offset or re-level the bed. Reduce the Z-offset in small increments until the first layer looks correct. Over-squishing can also cause the nozzle to clog, so be careful with this. Observe the first layer carefully for a consistent result.

Print Adhesion Issues

Poor print adhesion can be caused by various factors. If the nozzle is too far from the bed, the filament won’t stick. Also, make sure your bed is clean and free of any dust, oils, or other contaminants. Cleaning the bed with isopropyl alcohol can improve adhesion. Ensure you’re using the correct bed temperature for your filament. Using a brim or raft can help improve adhesion for more challenging prints. Make sure you are using the right filament. Some materials are notoriously difficult to stick to the bed.

Tips for Successful Prints

Achieving high-quality prints requires more than just proper Z-axis calibration. Following these tips will further enhance your 3D printing experience and improve your overall print results. Proper setup is important for printing, however, the material itself also plays a big role.

Choosing the Right Filament

Different filaments have different properties and require different bed temperatures. PLA is generally easy to print with, while ABS and PETG require higher temperatures and can be more prone to warping. Always check the filament’s recommended printing temperature and bed temperature. Ensure your bed surface is compatible with the filament you’re using. Using the right filament will make your experience easier. See image tevo-tarantula-z-axis-calibration-8.webp.

Optimizing Bed Adhesion

For improved bed adhesion, clean your print bed with isopropyl alcohol before each print. Use a brim or raft for prints with small footprints or those prone to warping. Applying a thin layer of glue stick or hairspray can also improve adhesion, especially with ABS and PETG. Ensure your bed is level, as an unlevel bed will cause adhesion issues. Adjusting your bed temperature can also make a difference. Experiment with the bed temperature within the filament’s recommended range until you find the optimal setting for your printer.

Maintaining Your Tevo Tarantula

Regular maintenance is essential for keeping your Tevo Tarantula in top condition and ensuring consistent print quality. Here are some maintenance tips to keep your printer running smoothly. Regular maintenance improves the reliability and lifespan of your 3D printer.